Our Services

With over 600 accredited testing methods and cutting-edge technology.

About LMATS

Leading the Way in Advanced Testing & Inspection

LMATS is an ISO/IEC 17025 and ISO 17020 accredited Australian company delivering over 600 methods of testing, inspection, and assessment across multiple industries.

Established: 2008 in Melbourne

National Presence: 10+ locations across VIC, NSW, QLD, WA

Projects Delivered: 100,000+

Clients Served: 200+ government departments, 3000+ companies

Powered by cloud-based OMS software with Level 3 NDT professionals and engineering qualifications. Your trusted partner for precision testing, sustainability-driven solutions, and real-time insights.

Learn More About Us

Objectives of Tank Inspections

The importance of Tank Inspection and condition monitoring is unquestionable in:

- avoiding failures

- maintaining safety

- optimising availability

Facilities with tanks often present additional risks beyond site risks such as

- Potential injury to site personnel

- Damage to equipment and lost business

- Tanks are often located in areas of environmental value

- The encroachment of suburbia, are close to the community.

- Legal issues and reputation damage.

A good tank inspection program is designed to:

- Show that tanks are not leaking and will not leak before next inspection

- Reduce the potential for un-planned releases

- Maintain tanks in safe operating condition

- Make repairs as required and have them tested to comply with standards and regulatory requirements

- Determine if and when replacement is necessary.

Typical process

To combat tank failures and confirm to regulations owner/operators are adopting for a more effective tank management and inspection programs. The flowchart below details a typical tank management process.

Online & Offline Inspections

Online inspections typically consist of:

- ultrasonic shell crawler runs

- ultrasonic roof measurements

- shell settlement evaluation (differential versus planar)

- with API-653 or EEMUA 159 visual external inspection.

Offline inspections typically consist of:

- MFL (Magnetic Flux Leakage) Floormap of the tank bottom plants

- with API-653 or API-650 or EEMUA 159 visual internal inspection.

Non-Destructive Testing

LMATS provide advanced NDT solutions for the inspection of storage tanks:

- Magnetic flux floor and plate scanners

- Ultrasonic shell crawlers

- Vacuum box testing

- Holiday detection

- ET Testing of Welds (including PEC, ECA and ACFM)

- Tank settlement survey

- SteerROVER™ a motorized steerable scanning solution for ultrasonic, phased array testing and corrosion mapping.

Engineering Support Team

LMATS certified inspectors & Engineering Support team can provide recommendations for repair or maintenance.

The results of the inspections are compiled into a concise report which can be supplied to the client both in hardcopy and electronically.

Repair recommendations, if any, are detailed in the report with reference to the applicable standard.

LMATS can also provide engineering solutions to difficult repairs and can provide engineering consultation on all tank design, operation and maintenance problems.

Construction Management

LMATS offers personnel suitably experienced with knowledge of:

- fabrication techniques and procedures

- storage tank construction

- non-destructive examination

- piping

- coatings

- review of modifications and as-built

- and progress monitoring.

Subcontract Management

LMATS offers subcontract management services that can support the prime contractor’s management for a specific project through the solicitation process, receipt of bids, bid analysis and tabulation, award through project execution and completion.

The Inspection of Storage Tanks Features:

- API-653 or EEMUA 159 certified inspectors.

- Inspection for various construction Standards or Codes e.g. API 650, BS 2654, AWWA D100, AS 1692, etc

- Inspection for various inspection Standard or Code e.g. API 653, EEMUA 159, STI SP001, AS 4971, etc.

Is your tank construction material as specified

Product Quality Inspections are Important, see how LMATS can help you save costs.

Are you receiving what you ordered?

Learn how LMATS can provide you with the assurity that the complete shipment of the same quality and meets the specification?

Contact us today and find out how an LMATS storage tank inspection services can ensure the safety and integrity of your tanks.

Cost savings of inspections by the reduced use of scaffold construction and removal, Elevated Work Platforms hire & rope access time.

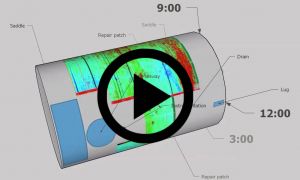

LMATS announce the addition of a motorized steerable scanning solution to its line of advanced NDT solutions for ultrasonic, phased array testing and corrosion mapping, SteerROVER™.

Inspect at heights without expensive scaffolding. Steer to hard-to-reach areas thanks to the scanner’s two pods with independent motors and four strong magnetic wheels.

LMATS remote inspection of Corrosion, thickness & weld assessment on the storage tanks, pressure vessels, LPG Spheres, overhead piping and structural elements is; fast, accurate, repeatable and traceable.

The LMATS remote inspection NDT solution techniques are:-

Fast, Accurate, Traceable a digital paper trail

Elevated Work Platform (EWP) vs Rope Access vs Scaffolding vs SteerROVER.

Same inspection, Same tank wall, corrosion mapping.

SteerROVER |

EWP |

Rope Access |

Scaffolding |

|---|---|---|---|

| Set Up – 1/2 Hour | Induction & setup – 2 Hour | Set Up – 1 Hour | Set Up – 12 Hours |

| Perform Works – 4 Hours | Perform Works – 6 Hours | Perform Works – 8 Hours | Perform Works – 8 Hours |

| Clear Site – 1/2 Hour | Clear Site – 1 Hour | Clear Site – 1 Hour | Clear Site – 12 Hours |

| Total – 5 Hours | Total – 9 Hours | Total – 10 Hours | Total – 32 Hours |

| A permit may be required | A permit may be required |

Configurations

The LMATS motorized steerable scanning solution, SteerROVER™ has different configurations depending on the application (weld, corrosion or visual inspection) and by combining different raster arms and cable length and camera options.

Remote Weld Inspection

The LMATS motorized steerable scanning solution SteerROVER™ can inspect welds when configured:

- Longitudinal welds on pipes as small as (305 mm) 12 inches and up to flat

- Internal, circumferential pipe range: 24 in. (610 mm) and above

- Circumferential pipe diameter range: 2.75 in. (70 mm) up to flat

Laser vision enables the unit to keep the weld being inspected in the centre of the probe thus maintaining an accurate scan.

Remote Corrosion Mapping

When configured and fitted with a motorized raster arm, the LMATS motorised steerable scanner SteerROVER™ is a powerful solution for corrosion inspection in remote locations.

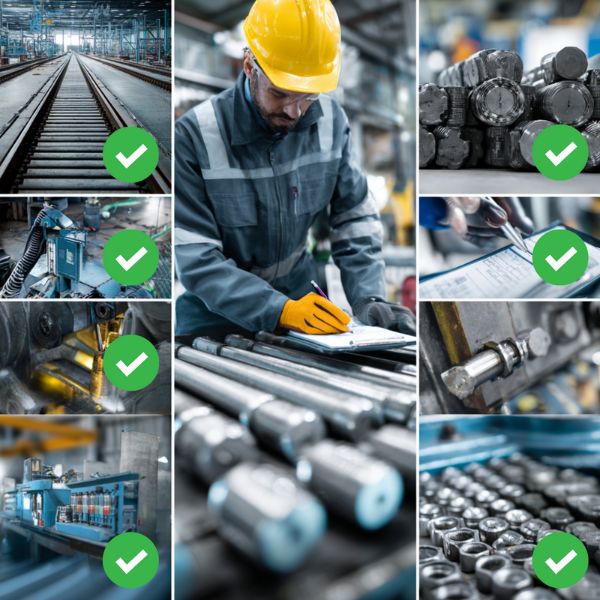

LMATS now offers a 3D image of the Remote Corrosion Mapping

The red heat map indicates areas of less than 2.5mm remaining wall thickness.

Data analysis of the linished patches revealed locations as low as 1.3mm remaining wall thickness.

Click on the image above to see the report.

Remote Visual Inspection

When fitted with digital still and video cameras, the LMATS motorised steerable scanner SteerROVER™ enables visual inspections in hard to get to places without the expense of EWP's, Ropework, scaffolding or drones.

The magnetic wheels provide the necessary traction to perform scanning at heights, such as on large pressure vessels or tanks and pipework.

Remote Inspection Features:

- Versatile steerable remote-control scanner to perform PAUT, TOFD, PEC, ECA, LFET, EMAT & visual inspection using various probes/camera holder configurations.

- Test speed – 15m/minute max. in ideal conditions

- 600mm scan width at 760mm/Sec in ideal conditions.

Remote Inspection Advantages:

- Improve safety by eliminating rope access work

- Reduce the cost of scaffold, EWP & rope access time

- Consistent & high-speed examination decrease onsite time and maintenance cost for the asset owner

- 100% coverage scanning mapped & recorded.

Remote Inspection Applications:

- Corrosion, erosion, wall loss, thickness mapping & weld assessment on storage tanks,

- Pressure vessels

- LPG Spheres

- Overhead piping

- Mining wear chutes

- Wear plates

- Marine hulls when in drydock

- wherein a scaffold, EWP or rope access is required to access the examination area.

- Risers, vertical piping, structural columns & beams

- Scanning on overhead pipes >70mm OD

- Scanning internally on pipes >610mm ID.

Remote Inspection Limitations:

- Unsuitable on non-ferromagnetic tanks

- However non-ferromagnetic pipes can be scanned using a chain attachment and drive system

- Unsuitable underwater applications

- Maximum 10kg payload capacity.

Contact us at one of the LMATS laboratories near you to discuss your remote inspection requirements. Quick contact on phoneline +61 3 9399 8145 or via the online form